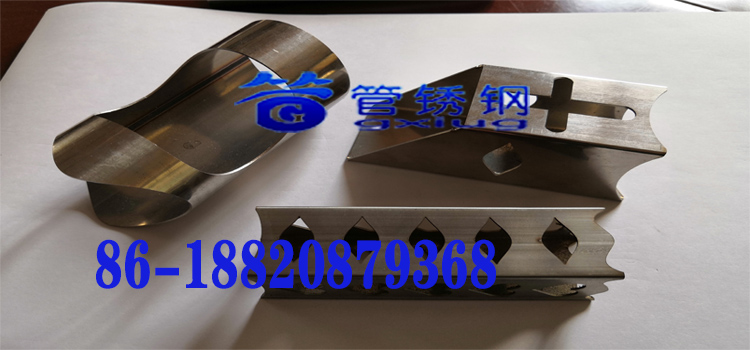

Since our company purchased the laser design last year, we have been able to process pipe diameters externally, not just the production of welded pipe machinery and welded pipe molds. In the laser cutting process, we are also seriously studying the advantages and disadvantages of laser drilling and traditional mechanical punching.

Laser tube cutting has the characteristics of faster speed, relatively accurate precision, and smoother nozzle. The traditional punching machine is relatively not so good, because it is stamped. And the nozzle is deformed a bit. In addition, for the speed, the mechanical punching can be designed to carry out multiple simultaneous, so the difference is not very big. It depends on the design.

Overall, I feel that laser cutting and hole drilling are still relatively good. If the financial pressure is low, it can be considered.Next : Different marking of welded pipe molds of different countries Back

Home

- [2020.05.18]Choose Guangdong welded …

- [2021.09.28]Difference between addin…

- [2021.09.26]Does the forming section…

- [2021.09.24]Effect of welded pipe ma…

- [2020.05.18]Welding machine producti…

- [2021.09.23]Will the mould of stainl…

- [2021.09.22]Precautions for producin…

- [2021.09.15]Factors needing attentio…

- [2021.01.20]Pipe-making and processi…

- [2021.09.11]Why finish machining aft…

- [2021.01.19]Analysis of pipe fitting…

- [2021.09.02]Production of simple clo…

- [2021.01.18]Which pipe welding machi…

- [2021.09.01]Is it better to use argo…

- [2021.08.28]Guide seat or palladium …

- [2021.01.16]Development trend of lon…

- [2021.08.27]Why are rags used in fro…

- [2021.01.15]Senwel technology-Guanxi…

- [2021.08.20]Can high frequency welde…

- [2021.01.14]Selection and precaution…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com