I have been engaged in the welded pipe industry for several years. For the welded pipe industry, whether the product tolerance can be effectively controlled is an important issue. If this is not done well, the pipe is often waste pipe. How should the stainless steel pipe making machine effectively control the tolerance range of the pipe? There are many factors to consider.

The first is whether the processing accuracy of the stainless steel pipe making machine is high, that is, whether the tolerance factor of the hardware can be controlled. If the tolerance of the pipe making machine itself is very large, it is also very difficult to produce more standard pipes, which is one of the factors to be considered.

The other is whether the production process of the mold of the stainless steel pipe making machine is appropriate and whether the tolerance control is reasonable, especially the runout tolerance. If this is not done well, the pipe will not be stable enough during operation, so the effect is naturally desired.

Another important factor is the personnel factor, which is also the technical factor. It belongs to the type of software. Good things should be operated by good technicians. In order to achieve the realm of "man-machine integration", it is very powerful.

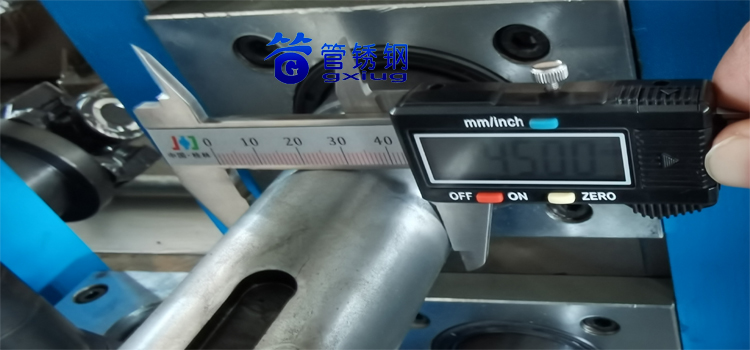

In my experience, the diameter tolerance of pipes produced by stainless steel pipe making machine can be controlled within 10 wires without the help of hardware. If it can be controlled within 5 wires with the help of workpieces, it depends on the opinions of customers.

Key words:stainless steel pipe making machine

Foshan GXG Technology Co., Ltd

web: http://www.fsgxiug.com

Tel: 86-18820879368(Wechat-Whatsapp)

E-mail: 345291578@qq.com

Next : Thick pipe and thin pipe have different design requirements for welded pipe mould Back

Home

- [2021.11.23]Why should there be more…

- [2021.11.22]Tolerance design and con…

- [2021.11.19]Is it better to have mor…

- [2021.11.18]How to select the leveli…

- [2021.11.17]Linkage lifting adjustme…

- [2021.02.20]Technical requirements o…

- [2021.11.16]What tools do welded pip…

- [2020.07.20]The technology of pipe w…

- [2021.11.15]High frequency pipe weld…

- [2021.02.19]Technical requirements o…

- [2020.04.14]Pipe welding mold is pro…

- [2021.02.18]Problems to be paid atte…

- [2021.11.10]How to design and apply …

- [2021.02.17]Cooperation between stai…

- [2021.11.06]How to choose the cuttin…

- [2021.02.16]Notes on combination of …

- [2021.02.16]How to improve the insta…

- [2021.11.03]How to deal with the dev…

- [2021.02.14]Straightening head insta…

- [2020.04.13]Adjustment mode of welde…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com